Regular maintenance, including inspections, cleaning, and calibration, is vital for frame repair equipment. Proactive care prevents issues, enhances productivity, saves costs, and extends the lifespan of critical tools, ensuring safer, more efficient collision repair services.

Frame repair equipment is a vital tool for professionals, but its true potential lies in consistent maintenance. Regular upkeep ensures optimal performance and longevity, translating to better results and cost savings. This article delves into the essential practices of regular maintenance, preventive care, and early detection of common issues, offering insights to maximize the efficiency of your frame repair equipment.

- Regular Maintenance: The Unsung Hero of Frame Repair

- Preventive Care: Extending Equipment Lifespan

- Common Issues: Early Detection and Quick Fixes

Regular Maintenance: The Unsung Hero of Frame Repair

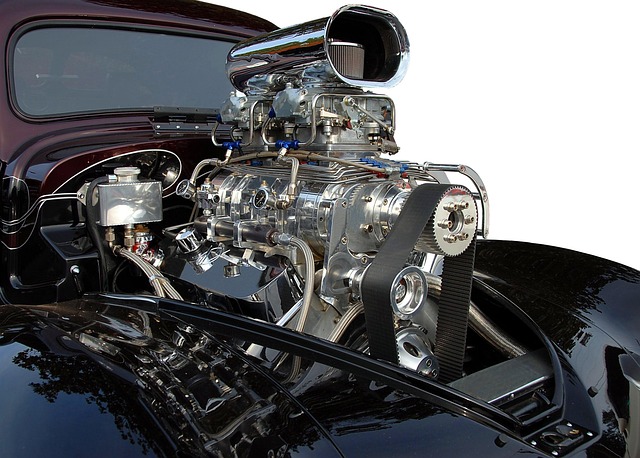

Regular maintenance is often an overlooked aspect when it comes to frame repair equipment, yet it plays a pivotal role in ensuring optimal performance and longevity. It’s akin to taking care of a fine machine—a well-maintained car dent repair or collision repair service equipment can make all the difference in the quality of repairs and the overall user experience. Just as regular tire services keep vehicles running smoothly, consistent maintenance for frame repair tools guarantees precision and efficiency.

By implementing scheduled servicing, cleaning, and calibration, technicians can identify potential issues early on, preventing costly breakdowns. This proactive approach not only enhances productivity but also safeguards against subpar repairs, which could lead to safety hazards in the case of vehicle frames. Regular checks ensure that every tool is in top condition, ready to tackle a wide array of frame repair tasks with accuracy and consistency.

Preventive Care: Extending Equipment Lifespan

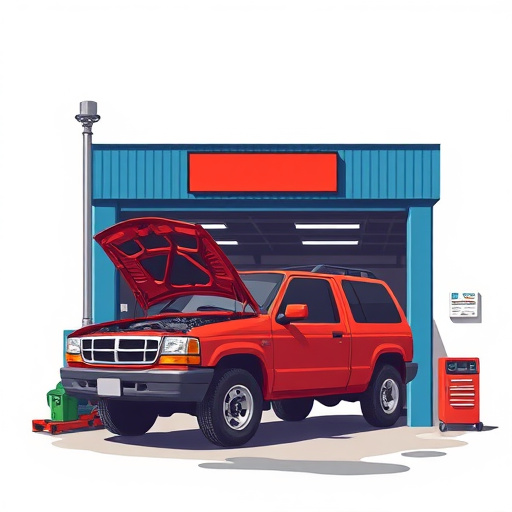

Regular maintenance plays a pivotal role in extending the lifespan of frame repair equipment and ensuring its optimal performance. Preventive care measures, such as routine inspections, cleaning, and lubrication, are essential components of any well-managed workshop. By adopting these practices, technicians can identify potential issues early on, preventing major breakdowns and costly repairs.

For instance, regularly checking welds, inspecting for signs of rust or corrosion, and maintaining proper tension on springs and cables are simple yet effective ways to preserve the integrity of frame repair tools. Similarly, keeping anautomotive body work station clean and well-oiled can significantly reduce friction points, prolonging the life of various equipment like welding machines and paint sprayers. This proactive approach not only saves businesses money in the long run but also contributes to the overall efficiency of collision repair services and automotive restoration processes.

Common Issues: Early Detection and Quick Fixes

Regularly checking your frame repair equipment for any signs of wear or damage is crucial to maintaining optimal performance. Common issues like faulty sensors, misaligned tools, or damaged components can lead to costly repairs and decreased efficiency if left undetected. Implementing a preventive maintenance schedule, which includes periodic inspections and quick fixes, can significantly extend the lifespan of your equipment.

Early detection of problems allows for simple solutions such as calibrating sensors, tightening loose connections, or replacing worn-out parts. These measures not only ensure seamless operation but also contribute to safer working conditions for technicians handling frame repair equipment. Remember, regular auto glass replacement and car paint repair services, alongside proper auto maintenance, are integral parts of keeping your frame repair equipment in top shape.

Proper maintenance of frame repair equipment is key to ensuring optimal performance, efficiency, and longevity. By implementing regular upkeep and preventive care practices, technicians can extend the lifespan of their tools while minimizing downtime and costly repairs. Early detection of common issues through routine checks allows for quick fixes, ultimately enhancing productivity in the frame repair process. Investing time in maintaining these essential tools pays dividends in delivering top-quality results to satisfied customers.